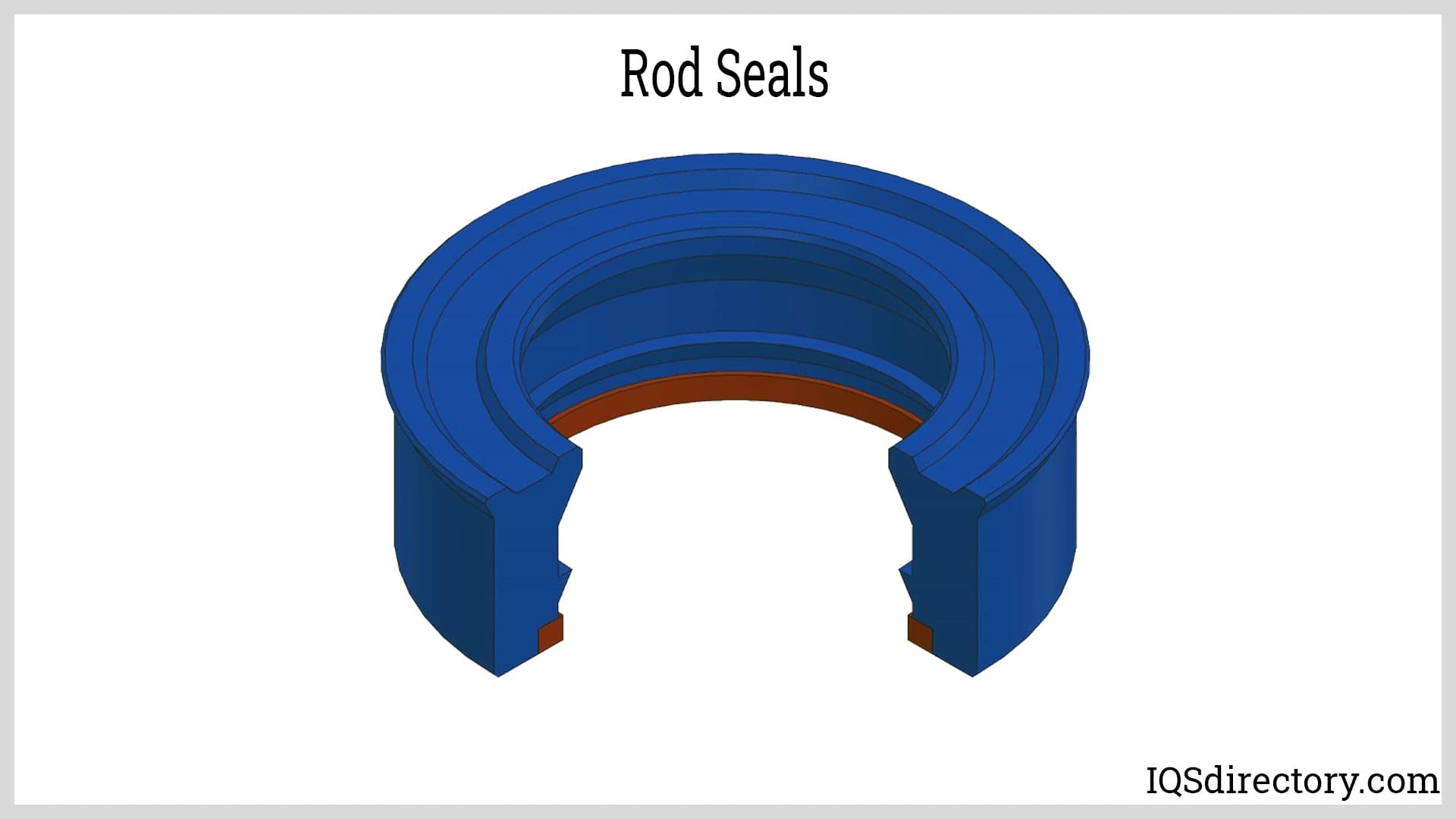

Any hydraulic or pneumatic cylinder system requires rod seals, sometimes called gland, head bush, or neck seals. They serve as a seal between the rod and gland of a cylinder. The rod seal is crucial in preventing leakage and corrosion because it functions as a pressure barrier to keep and control the working fluid when a cylinder is in dynamic motion. Read More…

MSP Seals was founded in 1998 in Indianapolis, IN. Our company has been a major supplier of seals and various other materials, continually innovating and responding to the changing needs of our customers. We have introduced unique new products, o-rings, hydraulic/pneumatic packings, oil seals, and other types of seals, MSP Seals also supplies molded rubber shapes and lathe cut shapes.

Garlock Sealing Technologies is the global leader in high-performance fluid sealing products for the world’s processing industries. Their 12 manufacturing facilities in the U.S., Canada, Europe, Asia and Latin America collectively produce the broadest range of fluid sealing products designed specifically for industrial applications. Some products include metal gaskets, o-rings and oil seals.

Kent Rubber Supply has been a trusted supplier of hydraulic seals since 1946. Focusing in exceeding customer service, we leverage the best equipment and the most knowledge staff to ensure we meet our customers unique needs. With our trusted experts, we determine the best rubber, foam, sponge or PVC material for your specific need. We continue serving customers both offshore and domestic.

Our list of inventory has grown since our founding over 20 years ago. We started small, but now offer an extensive product list of hydraulic seals, o rings, and other rubber products.

More Rod Seal Manufacturers

Rod seals are typically the decisive factor in ensuring that a hydraulic cylinder operates at its peak performance. However, since leaking through the rod seal may cause accidents and environmental harm, the proper seal must be chosen for every application. For example, although the system's fluid or gas is contained, leakage through a piston seal can lessen the system's efficacy. In addition, rod seals must be linked with a good wiper and gland housing design to ensure proper operation because the failure of a rod seal may cause exterior leakage.

Rod Seals Working Principle

Rod seals manage the difficult balancing act of producing a seal at high and low pressure. In addition to temperature changes between hot and cold, this commonly happens. They must therefore leave an oil film that is thin enough to be reintroduced into the cylinder after passing a trustworthy wiper seal. Therefore, when selecting a rod seal, it's critical to describe a region and provide exact specifications.

Rod Seal Manufacturing Process

Rod seals can be CNC-machined to specific measurements, including deviations from the original seal dimensions to account for worn rod or gland conditions. Then, depending on the application, basic rod seals can be quickly produced in various materials.

Types of Rod Seals

- Grooved Rod Seals: an anti-extrusion ring on the interior diameter of a single-acting seal.

- Rod Composite Seals: Powered by an O-ring, this sealing offers low friction and non-stick/non-slip durability.

- Rotary Rod Seals: for sealing a revolving shaft.

- Rubber & Fabric Seals: when the application calls for a material of this type.

- T-Seals: two backup rings on a T-shaped seal to help stop extrusion.

- Vee-Packing (Chevron) Seals: Multiple-lipped seals are used in medium- to heavy-duty applications that are grouped in groups of three or five.

Additional Types of Rod Seals

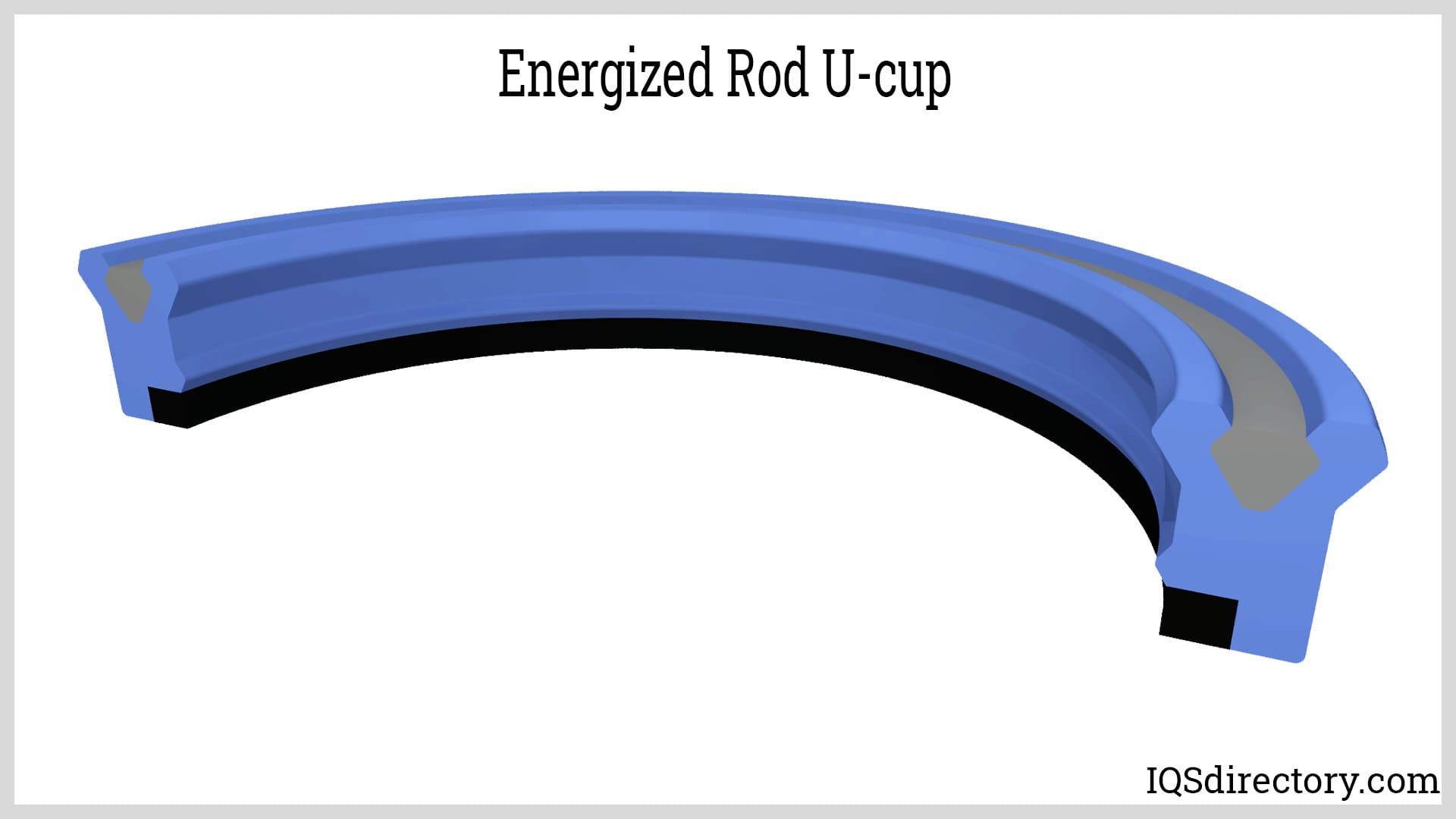

Rod U-CUP O-Ring Energized

The Rod U-Cup O-ring energized is a single-acting, twin-lipped, electrified polyurethane O-ring for hydraulic cylinder rod seals. This O-ring helps increase the sealing force at zero or low pressure to stop leaks. Additional gland stability is provided by the secondary sealing lip, which is situated behind the primary sealing lip. The beveled sealing lip faces the rod to improve low to high-pressure sealing and wiping action. Compared to traditional symmetrical U-Cups, the inner sealing lip is shorter and more durable to improve sealing and compression set properties. For heavy-duty applications, a backup ring can be utilized with the U-Cup, which is made to fit inside the seal housing with interference.

Rod U-Cup Stabilized

The Rod U-Cup Stabilized is a single-acting dual-lipped polyurethane hydraulic cylinder rod seal. Additional gland stability is provided by the secondary sealing lip, which is situated behind the primary sealing lip. The beveled sealing lip faces the rod to improve low to high-pressure sealing and wiping action. Compared to traditional symmetrical U-Cups, the inner sealing lip is shorter and more durable to improve sealing and compression set properties. For heavy-duty applications, a backup ring can be utilized with the U-Cup, which is made to fit inside the seal housing with interference.

Rod U-Cup O-Ring Energized Bur

A hydraulic cylinder rod seal with an anti-extrusion ring at its heel, the Rod U-Cup O-ring Energized BUR is made of high-performance polyurethane twin-lipped O-rings. The O-ring helps increase the sealing force at zero or low pressure to stop leaks. Additional gland stability is provided by the secondary sealing lip, which is situated behind the primary sealing lip. The backup ring aids the seal's resistance to side loading and sudden pressure increases. The beveled sealing lip faces the rod to improve low to high-pressure sealing and wiping action. Compared to traditional symmetrical U-Cups, the inner sealing lip is shorter and more durable to improve sealing and compression set properties. In addition, the U-Cup is made to fit inside the seal housing with interference.

Rod Buffer Cap Seal

A single-acting, O-ring-energized PTFE rod seal called the Rod Buffer Cap Seal is utilized in dynamic sealing applications. The seal is put into closed grooves, including those that comply with ISO 7425. The seal assembly is particularly suited for high-speed applications since it has low friction and prevents stick slip. One can use the Rod Buffer Cap seal alone or with other rod seals. The primary rod seal is most frequently protected from pressure spikes by using it as a pressure buffer. High wear resistance, low break-out force, and extrusion resistance are all features of this buffer cap seal.

Despite these seals' widespread use, it is wise to exercise caution to avoid potential risks. The single-acting seals are utilized the most frequently. When using these rod seals, the pressure inside the cylinder only affects one seal side. Up to 5800 psi of pressure can be applied to the rod side of the piston (400 bar). At times, these demands may even be greater. This pressure is one of the elements influencing the forces acting on the rod seal and surface. Therefore, it is advised that rod surfaces be created to the requirements, and the materials used to make rod seals should be resistant to wear.

Choosing the Right Rod Seal Manufacturer

To ensure you have the most positive outcome when purchasing rod seals from a rod seal manufacturer, it is important to compare several companies using our directory of rod seal manufacturers. Each rod seal manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rod seal business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple rod seal companies with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services